- Applicable Belt Dia.(Ø)

- 2

- 3

- 4

- 5

- 6

- 8

- 10

- Pitch Circle Dia. P.D.(Ø)

- 15

- 20

- 23

- 28

- 30

- 38

- 40

- 45

- 48

- 50

- 60

- 75

- 100

- 140

- Material

- Aluminum

- EN AW-5052 Equiv.

- Surface Treatment

- Shaft Dia. d (or P)(Ø)[3-20/1Ø unidades]

- R(mm)

- 1.1

- 1.6

- 2.1

- 2.6

- 3.1

- 4.1

- 5.1

- Type

- CAD

- 2D

- 3D

- Dias de envio estimados

- Tudo

- Dentro de 10 dias úteis

Round belt pulleys / half-round groove double / grub screw clamping / stainless steel, aluminium / anodised

Número da peça:

candidatos encontrados.Desenho de contorno e tabela de especificações

Back to the Category Round Belt Pulleys, Idlers

Technical Drawing - Round Belt Track Rollers

Open the technical drawing in the new window

Available dimensions and tolerances can be found under the tab More Information.

Basic Properties (e.g., material, hardness, coating, tolerance) - Round Belt Track Rollers

| Type | Material | Surface Treatment | Accessory |

| MBWAC | Aluminum Alloy 5000 series | Clear Anodize | Set Screw 2 pcs. (EN 1.4301 Equiv.) |

| MBWS | EN 1.4301 Equiv. | - |

Further specifications can be found under the tab More Information.

Composition of a Product Code - Round Belt Track Rollers

| Part Number | - | R | - | Shaft Bore Specification, I.D. |

| MBWS30 | - | 1.6 | - | P5 |

Alterations - Round Belt Track Rollers

General Information - Round Belt Track Rollers

Selection details of round belt discs/idler pulleys

- Material: aluminum, steel, stainless steel, resin type (polyacetal)

- Coatings: untreated, burnished, nickel-plated, anodized

- Groove shape: V-groove (trapezoid groove), U-groove

- Belt diameter: single groove, double groove

- Effective diameter: 2 to 10 mm

- Shaft diameter: 15 to 140 mm

- Mounting: 3 to 20 mm

Description/Basics

The round belt disk for mechanical engineering is generally intended for drive and power transmission.

A system with round belts and round belt disk can transmit force over larger distances. An idler pulley is recommended depending on the distance to the guide. This reduces oscillations in a belt drive and minimizes the risk of the belt jumping off the round belt pulley. In addition, the belt tension of a round belt is important for power transmission. Depending on the application, the tension can be produced via a round belt disk with integrated ball bearing (tension roller). In addition, the use of a tension roller can increase the wrap angle and thus the contact surface of the belt on the round belt disk. Round belt disks made of plastic are often used for tensioning the round belt.

In principle, MISUIM offers two types of round belt discs. These are available with a trapezoidal groove (V-groove) or radius (U-groove) suitable for the round belt. The V-groove round belt disks are adapted to the round belt and offer the advantage that they form up to three contact points for the round belt due to their shape. In comparison, round belt disks with a V-groove can thus have a higher slip torque.

MISUMI also offers round belt disks with two grooves for drives mounted side-by-side. The combination of two round belt disks can be absorbed with force and simultaneously released and forwarded. In pulleys for round belts with double grooves, the force can also be delivered in different directions or systems. Therefore, it may be possible to forgo a drive unit and reduce costs.

The drive wheels for round belts can be fastened on a axles / rotary shafts in various ways. A flat round belt disk is mounted on an axle using a clamping screw. MISUMI also offers this as a round belt disk with hub and optionally with keyways. Another commonly used variant is the belt pulley with clamping scar.

The belt pulleys for round belts can often be found in transport technology to convey light objects. These are usually operated in a permanent and constant transport.

If higher forces occur in a system and any slip is undesirable, a timing pulleys can be used.

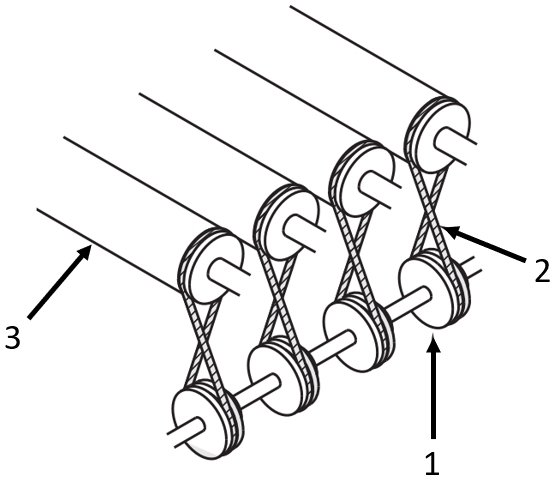

Application Examples - Round Belt Track Rollers

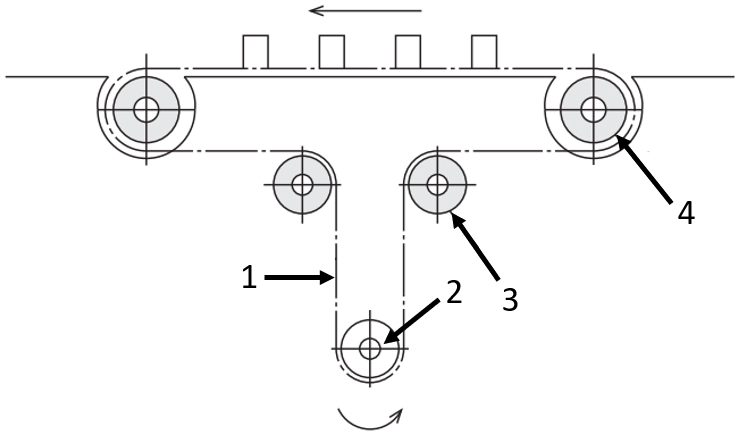

Application example conveyor belt

(1) Round belt disk with double groove, (2) rotary shaft, (3) Round belt, (4) Workpiece

Application example conveyor belt

(1) Round belt, (2) Motor, (3) Idler pulley/return roller, (4) Drive wheel for round belt

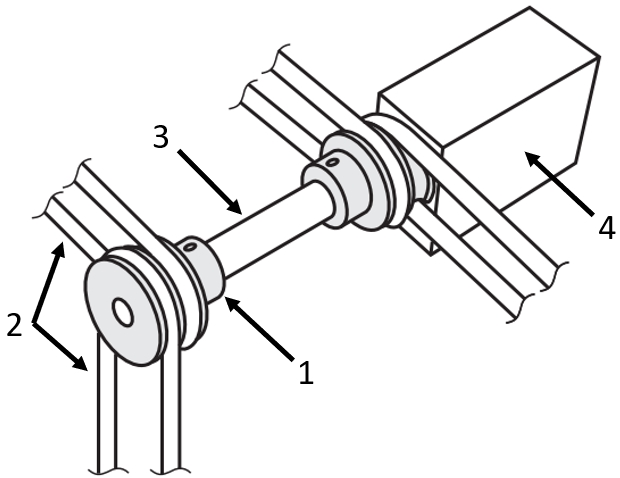

Application example

(1) Round belt disc with hub, (2) round belt, (3) rotary shaft, (4) bearing housing

Industrial Applications

Lista de números de peça

| Número da peça |

|---|

Preço unitário (excluindo IVA)(Preço unitário incluindo IVA) | Data de envio standard |

|---|

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

- ( - ) | 10 dias úteis |

Informações detalhadas

Contorno e especificações

Back to the Category Round Belt Pulleys, Idlers

Technical Drawing - Round Belt Track Rollers

Open the technical drawing in the new window

Specification Tables - Round Belt Track Rollers

| Part Number | R | Shaft Bore Specification, I.D. | S | D | D1 | D2 | L | ℓ | B | M (Coarse) | Accessory: Set Screw | Applicable Round Belt Dia. | Unit Price | ||

| Type | P.D. | P (H7) 1mm Increment | MBWAC | MBWS | |||||||||||

| MBWAC MBWS | 15 | 1.1 | 3~8 | 4 | 12 | 17 | 13 | 14 | 3 | 5.8 | M3 | M3x3 | 2 | ||

| 20 | 4~10 | 16 | 22 | 18 | |||||||||||

| 30 | 4~12 | 20 | 32 | 28 | |||||||||||

| 20 | 1.6 | 3~10 | 5 | 16 | 22 | 17 | 16 | 3 | 5.8 | M3 | M3x3 | 3 | |||

| 30 | 5~12 | 20 | 32 | 27 | |||||||||||

| 40 | 42 | 37 | |||||||||||||

| 45 | 5~20 | 30 | 47 | 42 | |||||||||||

| 23 | 2.1 | 5~12 | 6 | 20 | 25 | 19 | 18 | 3 | 5.8 | M3 | M3x3 | 4 | |||

| 28 | 30 | 24 | |||||||||||||

| 30 | 32 | 26 | |||||||||||||

| 40 | 42 | 36 | |||||||||||||

| 45 | 5~18 | 25 | 47 | 41 | 20 | 4 | 7.8 | M4 | M4x3 | ||||||

| 48 | 5~20 | 30 | 50 | 44 | |||||||||||

| 28 | 2.6 | 5~12 | 7 | 20 | 30 | 23 | 20 | 3 | 5.8 | M3 | M3x3 | 5 | |||

| 40 | 5~20 | 30 | 42 | 35 | 22 | 4 | 7.8 | M4 | M4x3 | ||||||

| 50 | 52 | 45 | |||||||||||||

| 28 | 3.1 | 5~12 | 8 | 22 | 30 | 22 | 22 | 3 | 5.8 | M3 | M3x3 | 6 | |||

| 38 | 5~20 | 30 | 40 | 32 | 24 | 4 | 7.8 | M4 | M4x3 | ||||||

| 48 | 50 | 42 | |||||||||||||

| 50 | 52 | 44 | |||||||||||||

| 60 | 62 | 54 | |||||||||||||

| 75 | 77 | 69 | |||||||||||||

| 100 | 102 | 94 | |||||||||||||

| 50 | 4.1 | 5~20 | 10 | 30 | 52 | 42 | 30 | 5 | 9.8 | M5 | M5x4 | 8 | |||

| 60 | 62 | 52 | |||||||||||||

| 100 | 102 | 92 | |||||||||||||

| 60 | 5.1 | 5~20 | 12 | 34 | 62 | 50 | 34 | 5 | 9.8 | M5 | M5x4 | 10 | |||

| 100 | 102 | 90 | |||||||||||||

| 140 | 142 | 130 | |||||||||||||

Alterations - Round Belt Track Rollers