Estamos a traduzir a nossa loja para português!

Mas como temos muitos produtos e páginas, vai demorar algum tempo. Entretanto, o nosso catálogo de produtos estará em inglês. Obrigado pela sua paciência!

Condições de filtragem

- Material

- Steel

- EN 1.2379 Equiv.

- EN 1.7220 Equiv.

- EN 1.7242 Equiv.

- Mounting Side Dia. D(Ø)

- 6

- 8

- 10

- 10T

- 12

- 16

- 20

- Heat Treatment

- Insertion Guide Section Outer Dia. P(Ø)[8-35/0.1Ø unidades]

- Mounting Section Length L(mm)

- 5

- 8

- 10

- 12

- 15

- 18

- 20

- Positioning Part Length B(mm)[2-30/1mm unidades]

- CAD

- 2D

- Dias de envio estimados

- Tudo

- Dentro de 7 dias úteis

- Dentro de 9 dias úteis

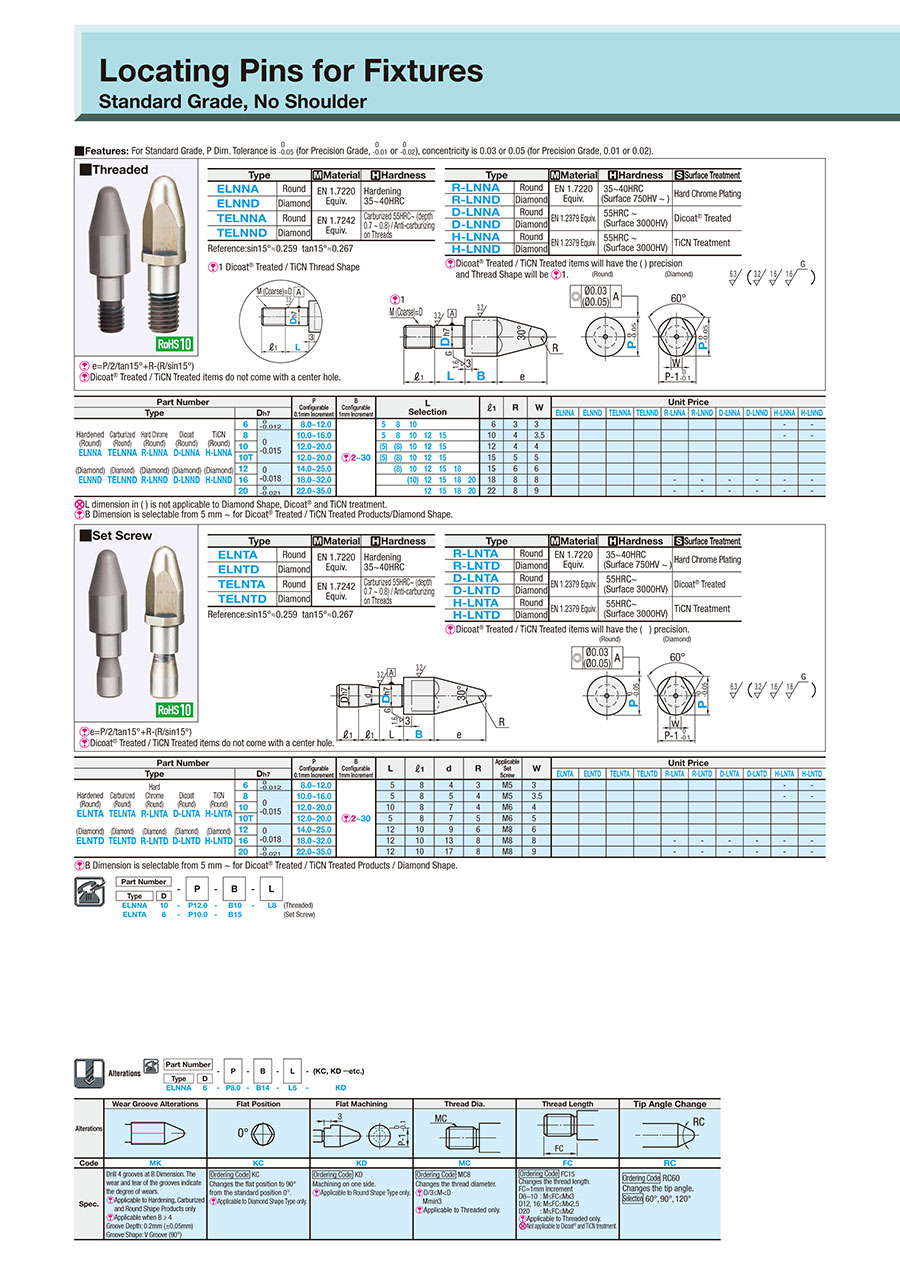

Jig Pins / Standard(h7) / Threaded

Número da peça:

candidatos encontrados.Desenho de contorno e tabela de especificações

Dimensional Drawing

※1

Thread Shape of Dicoat Treated products / TiCN products

(Round)

(Diamond)

※1

[ ! ] e = P/2 ÷ tan 15° + R - (R ÷ sin 15°) Reference: sin 15° ≒ 0.259, tan 15° ≒ 0.267

[ ! ] Unless otherwise specified, the dimension tolerance conforms to JIS B 0405 Class m. However, threaded length and angular dimension tolerances are excluded.

[ ! ] The coaxiality of Dicoat treated and TiCN treated products will have the precision in ( ), and the thread shape will be *1.

[ ! ] Dicoat Treated / TiCN Treated items do not come with a center hole.

[ ! ] Regarding tightening torque (reference value), the strength class for Dicoat treated and TiCN treated products: 8.8, and for others: 10.9.

Furthermore, it is not applicable when using locking materials or lock washers.

| Type | [M] Material | [H] Hardness | [S] Surface Treatment | |

| ELNNA | Round | EN 1.7220 Equiv. | Hardened 35 to 40HRC | ‐ |

| ELNND | Diamond | |||

| TELNNA | Round | EN 1.7242 Equiv. | Carburized 55HRC or more (Depth 0.7 to 0.8) | |

| TELNND | Diamond | |||

| R-LNNA | Round | EN 1.7220 Equiv. | 35 to 40HRC (Surface 750HV or more) | Hard Chrome Plating |

| R-LNND | Diamond | |||

| D-LNNA | Round | EN 1.2379 Equiv. | 55HRC or more (Surface 3000 HV) | Dicoat Treated |

| D-LNND | Diamond | |||

| H-LNNA | Round | 55HRC or more (Surface 3000 HV) | TiCN Treatment | |

| H-LNND | Diamond | |||

Tightening Torque Table

| Nominal of thread | 8.8 | ||

| Yield Load | Initial Tightening Force | Tightening Torque | |

| N{kgf} | N{kgf} | N ・cm{kgf・cm} | |

| M6 | 12867 {1313} | 9006 {919} | 784{80} |

| M8 | 23422 {2390} | 16395 {1673} | 1911{195} |

| M10 | 37113 {3787} | 25980 {2651} | 3783{386} |

| M12 | 53949 {5505} | 37759 {3853} | 6605{674} |

| M16 | 100470 {10252} | 70325 {7176} | 16366{1670} |

| M20 | 161592 {16489} | 113112 {11542} | 32928{3360} |

| Nominal of thread | 10.9 | ||

| Yield Load | Initial Tightening Force | Tightening Torque | |

| N{kgf} | N{kgf} | N ・cm{kgf・cm} | |

| M6 | 18894 {1928} | 13220 {1349} | 1156{118} |

| M8 | 34398 {3510} | 24079 {2457} | 2803{286} |

| M10 | 54508 {5562} | 38161 {3894} | 5557{567} |

| M12 | 79223 {8084} | 55458 {5659} | 9702{990} |

| M16 | 147549 {15056} | 103282 {10539} | 24108{2460} |

| M20 | 230261 {23496} | 161181 {16447} | 46942{4790} |

[ ! ] Tightening Conditions: Use a torque wrench (Surface oil lubrication, torque coefficient k = 0.17, tightening coefficient Q = 1.4)

This table has been excerpted and edited from the catalog of KYOKUTO MFG. CO., LTD.

The torque coefficient varies depending on the conditions of use. Please use the values as a reference.

Specification Table

| Part Number | — | P | — | B | — | L | |||

| Type | D | ||||||||

| ELNNA | 10 | — | P12.0 | — | B10 | — | L8 | (Threaded) | |

| Part Number | P Ordering Code 0.1 mm Increments | B Ordering Code 1 mm Increments | L Selection | ℓ1 | R | W | |||||||||

| Type | Dh7 | ||||||||||||||

| Round | Diamond | ||||||||||||||

| ELNNA TELNNA R-LNNA D-LNNA H-LNNA | ELNND TELNND R-LNND D-LNND H-LNND | 6 | 0 -0.012 | 8.0 to 12.0 | [ ! ] 2 to 30 | 5 | 8 | 10 | 6 | 3 | 3 | ||||

| 8 | 0 -0.015 | 10.0 to 16.0 | 5 | 8 | 10 | 12 | 15 | 10 | 4 | 3.5 | |||||

| 10 | 12.0 to 20.0 | (5) | (8) | 10 | 12 | 15 | 12 | 4 | 4 | ||||||

| 10T | 12.0 to 20.0 | (5) | (8) | 10 | 12 | 15 | 15 | 5 | 5 | ||||||

| 12 | 0 -0.018 | 14.0 to 25.0 | (8) | 10 | 12 | 15 | 18 | 15 | 6 | 6 | |||||

| 16 | 18.0 to 32.0 | (10) | 12 | 15 | 18 | 20 | 18 | 8 | 8 | ||||||

| 20 | 0 -0.021 | 22.0 to 35.0 | 12 | 15 | 18 | 20 | 22 | 8 | 9 | ||||||

[ ! ] For Dicoat Treated / TiCN Treated products and the Diamond Shape, the value of 5 mm or more can be configured for the B dimension.

Alterations

| Alterations Code | Alteration Details | Application Conditions | Ordering Example | |

| MK | Wear Groove Alterations | Drill 4 grooves on the B dimension area. Abrasion management can be facilitated by checking the wear and tear of the grooves. Groove Depth: 0.2 mm (±0.05 mm) Groove Shape: V Groove (90°) | [ ! ] Applicable to Hardening, Carburized and Round Shape Products only [ ! ] Applicable when B ≥ 4 | ELNNA6-P8.0-B14-L5-MK |

| KC | Flat Position | Changes the flat position to 90° from the standard position 0°. | [ ! ] Applicable to Diamond Shape Type only | ELNND8-P12.5-B15-L8-KC |

| KD | Flat Machining | Machining on one side. | [ ! ] Applicable to Round Shape Type only | ELNNA6-P8.0-B14-L5-KD |

| MC | Thread Dia. | Changes the thread diameter. Ordering Code: MC8 | [ ! ] D/3 ≤ M < D, Mmin3 [ ! ] Applicable to Threaded Type only | TELNNA10-P13.2-B12-L10-MC8 |

| FC | Thread Length | Changes the thread length. Ordering Code: FC15 | FC = 1 mm Increments D6 to 10: M ≤ FC ≤ Mx3 D12·16:M ≤ FC ≤ Mx2.5 D20: M ≤ FC ≤ Mx2 [ ! ] Applicable to Threaded Type only [NG] Not applicable to Dicoat and TiCN treatment | TELNNA10-P13.2-B12-L10-FC15 |

| RC | Tip Angle Change | Changes the tip angle. Selection: 60°, 90°, 120° Ordering Code: RC60 | - | ELNNA6-P8.0-B14-L5-RC60 |

Lista de números de peça

Número de itens

| Número da peça |

|---|

Preço unitário (excluindo IVA)(Preço unitário incluindo IVA) | Data de envio standard |

|---|

- ( - ) | 7 dias úteis |

- ( - ) | 7 dias úteis |

- ( - ) | 7 dias úteis |

- ( - ) | 7 dias úteis |

- ( - ) | 7 dias úteis |

- ( - ) | 7 dias úteis |

- ( - ) | 7 dias úteis |

- ( - ) | 7 dias úteis |

- ( - ) | 7 dias úteis |

- ( - ) | 7 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |

- ( - ) | 9 dias úteis |