- Caster Type

- [H] Mounting Height(mm)

- 160

- 178

- Thread Dia. M

- [D] Wheel Diameter(mm)

- 100

- 125

- Wheel Width B(mm)

- 28

- 32

- CAD

- 2D

- 3D

- Dias de envio estimados

- Tudo

- Dentro de 5 dias úteis

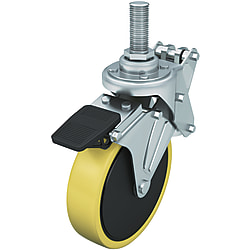

Castors / Vibrations Insulating

Número da peça:

candidatos encontrados.Desenho de contorno e tabela de especificações

CMPR

(Plate Type)

CMPRS

(Plate Type)

CMPG

(Screw-In Type)

CMPGS

(Screw-In Type)

| Main Body | Wheel | Bearing | |||

| [M] Material | [S] Surface Treatment | [M] Material | Specific Volume Resistivity | Swiveling Part | Wheel |

| EN 1.4301 Equiv. | Barrel Grinding | Antistatic Urethane | 108Up to 109Ω·cm | Provided | Provided |

Specification Table

| Part Number | — | Wheel Material |

| CMPR100 | — | S |

| Main Body Type | Part Number | Wheel Material | H Stroke | d | E1 | E2 | r1 | r2 | Y1 | Y2 | K1 | K2 | B | Applicable Load (N) | Mass (g) | ||

| Type | D | H1 (max) | H2 (min) | ||||||||||||||

| Swivel | CMPR | 100 | S (Antistatic Urethane) | 162 | 148 | 8.8 | 20 | 34 | 71 | 85 | 71 | 78 | 61 | 46 | 28 | 150 or more 300 | 1100 |

| 125 | 180 | 166 | 25 | 39 | 89 | 103 | 77 | 83 | 77 | 62 | 32 | 1258 | |||||

| Swivel + With Stopper | CMPRS | 100 | 162 | 148 | 20 | 34 | 95 | 94 | 71 | 78 | 61 | 46 | 28 | 1212 | |||

| 125 | 180 | 166 | 25 | 39 | 110 | 110 | 77 | 83 | 77 | 62 | 32 | 1381 | |||||

| Main Body Type | Part Number | Wheel Material | H Stroke | E1 | E2 | r1 | r2 | Y1 | Y2 | K1 | K2 | B | Applicable Load (N) | Mass (g) | ||

| Type | D | H1 (max) | H2 (min) | |||||||||||||

| Swivel Screw-In | CMPG | 100 | S (Antistatic Urethane) | 160 | 146 | 20 | 34 | 71 | 85 | 71 | 78 | 61 | 46 | 28 | 150 or more 300 | 1062 |

| 125 | 178 | 164 | 25 | 39 | 89 | 103 | 77 | 83 | 77 | 62 | 32 | 1218 | ||||

| Swivel Screw-In + Stopper | CMPGS | 100 | 160 | 146 | 20 | 34 | 95 | 94 | 71 | 78 | 61 | 46 | 28 | 1174 | ||

| 125 | 178 | 164 | 25 | 39 | 110 | 110 | 77 | 83 | 77 | 62 | 32 | 1341 | ||||

Lista de números de peça

| Número da peça |

|---|

Preço unitário (excluindo IVA)(Preço unitário incluindo IVA) | Data de envio standard |

|---|

106.42 € ( 126.64 € ) | 5 dias úteis |

112.08 € ( 133.38 € ) | 5 dias úteis |

115.24 € ( 137.14 € ) | 5 dias úteis |

118.38 € ( 140.87 € ) | 5 dias úteis |

Informações detalhadas

Informações básicas

[Features] This roller for clean rooms can absorb vibrations even on uneven surfaces.

Contorno e especificações

Specifications/Overview

■Yield problems expected with the conventional wheels

When a workpiece is being conveyed into a clean room, casters are traveling over steps or

grating surfaces and vibrations from the floor are transmitted to a cart. Vibrations not only causes dust from casters and a cart but also may possibly transmitting impacts on important workpiece.

(2) Generation of Particles due to Vibrations

Vibrations by casters traveling lift dusts around the floor surface and down flow air system may not be able to control the particle amounts.

(3) Anti-static Countermeasures

Dusts adhering to the rubber/urethane wheels of conventional casters, which accumulate static electricity generated by friction

between wheels and the floor and may cause a spark discharge.

■Basic Structure of Vibration Damper

Shocks received by a caster when going over a stepped terrain are absorbed by a spring,

then dampened by a viscoelastic member.

A New mechanism provides solutions for conventional spring-loaded casters on insufficient vibration damping, and solutions

for the urethane type on degradation-inducing durability losses.

It also provides excellence in safety with no damping gas leaks.

■Effect of Vibration Absorption

Compared with normal casters, the decrease in vibrations has dramatically improved.

Casters used: CMPG100-S (Vibration Damping Casters)

Urethane Wheel Diameter ø100

(Normal Caster)

Protrusion: Semicircular, R = 2.5 mm

Protrusion Intervals: Per 1 m

Load: 201 N

Running Speed: 4 km/h

■Features of Caster with Vibration Damper

·Protects transported equipment by absorbing and damping vibrations from the floor.

·Controls particulate generation caused by vibrations, and improves production yields.

·Prevents static electricity from being generated on the floor with antistatic wheels.

■Particle Generation Comparison

Compared with normal casters, particle volume is reduced to 1/4.

■Specific Volume Resistivity of Wheels

| 100 | 102 | 104 | 106 | 108 | 1010 | 1012 | 1014 |

Antistatic Urethane 108Up to 109Ω·cm | |||||||

| Electric Conductivity | Antistatic Performance | Insulation | |||||

Rubber Wheels

1015~Ω·cm

| Damper Type | Shock Absorption | Vibration Transmission Time | Allowable Load | Safety | Service Life |

| No Damper (Normal Caster) | × | × | ◎ | ○ | ○ |

| Spring | ○ | × | △ | ○ | △ |

| Urethane Cushioned | ○ | △ | △ | △ | × |

| Shock Absorber | ○ | ○ | △ | × | △ |

| * Casters with Vibration Damper | ○ | ◎ | ○ | ○ | ○ |